FREQUENTLY ASKED QUESTIONS FOR CO2 LASER MACHINE

Published:

2020-01-01

FREQUENTLY ASKED QUESTIONS FOR CO2 LASER MACHINE

HOW TO USE A LASER MACHINE?

HOW DOES CO2 LASER CUTTING MACHINE WORKS?

Laser cutting is a type of thermal separation process. The laser beam hits the surface of the material and heats it so strongly that it melts or completely vaporizes. Once the laser beam has completely penetrated the material at one point, the actual cutting process begins. The laser system follows the selected geometry and separates the material in the process. Depending on the application, the use of process gases can positively influence the results.

HOW DOES CO2 LASER ENGRAVING WORK?

During the process of laser engraving, the laser beam impinges on the material, exposing it to a great deal of heat. Depending on the exposure time, the color changes and creates a contrast, or the material evaporates or burns. The resulting laser engraving is permanent and very resistant to abrasion.

WHICH GRAPHICS PROGRAMS ARE COMPATIBLE WITH JW LASER MACHINES?

For the JW CO2 Laser Cutting and Engraving Machines you can download the followings links:

· Corel, Adobe Illustrator, AutoCad, Solidworks etc. Any vector design and editing software.

· Laser Machine Control Software: RDWorks, Additional Software provided.

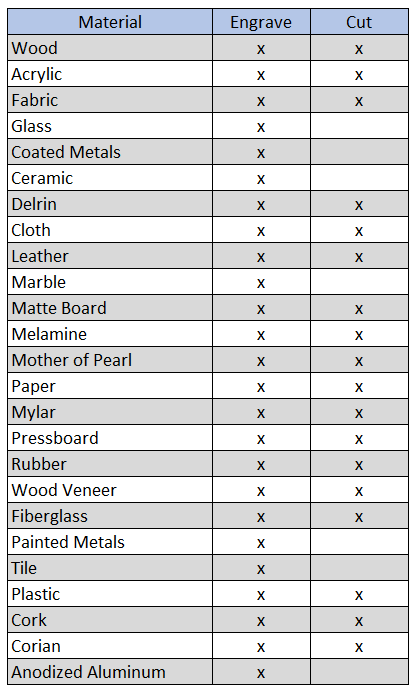

WHAT MATERIALS CAN I ENGRAVE, AND CUT USING A CO2 LASER?

WHAT IS INCLUDED IN THE PURCHASE FROM JW?

· Exhaust fan

· Air exhaust pipe

· Industrial water chiller

· Include both honeycomb and knife-blade work table

· Automatic up-and-down work table with up to 9" clearance to accommodate rotary attachment and tall objects

· Three-in-one combiner block integrate red-beam, first mirror and beam combiner for easy beam alignment and quick diagnostic of optics issues)

FOR WORKFORCE SERIES

· Exhaust fan

· Air exhaust pipe

· Industrial water chiller

· Knife blade for supporting various materials or optional conveyor type table with auto-feeding (optional)

FOR FABRIC CUTTING MASTER SERIES

· Exhaust fan

· Air exhaust pipe

· Industrial water chiller

· Three-in-one combiner block integrate red-beam, first mirror and beam combiner for easy beam alignment and quick diagnostic of optics issues (optional for the Fabric Cutting Master Series with auto feeder)

· Automatic conveyor table and feeder to accommodate roll fabric materials with infinite length (included for Fabric Cutting Master Series with conveyor belt and feeder)

INSTALLATION AND TRAINING

· Do you offer onsite install service for a CO2 laser cutting machine?

Yes, we offer onsite install with a fee, contact us for pricing. Most of the CO2 laser machine sales are user self-install.

· How do I install a laser machine?

Training video will be provided when you purchase our machine.

· How long does it take to assemble a CO2 Laser Machine?

Typically, it takes 1 day for first timer. 1-2 hours for experienced user.

LASER MAINTENANCE AND SAFETY

· How to get support after warranty time?

Contact BesCutter for support. We will help you beyond the warranty time.

· What is the lifetime of a CO2 laser machine?

Laser tube vendor often mention 10,000 hours service hour for laser tube. In reality it is about 2-3 years.

Devin Loo

Sales manager

Tel/Wechat:+8619963537926

Whatsapp:+8615922225006

Facebook:Devin Loo

Telegram:+8619963537926

Email : jwdevin@chinajwlaser.com

Web:www.chinajwlaser.com

Latest News

CONTACT US

Please Send The Contact Email To

Welcome to inquire

LIAOCHENG JINGWEI LASER EQUIPMENT CO.,LTD

Address:No. 111, Baililai Kechuang Town, Intersection of Hunan Road and Xindonghuan, Liaocheng High-tech Zone, Liaocheng, Shandong, China

Whatsapp:+86-19963537926

Mob:+86-19963537926

MESSAGE