Laser Marking Machine for PCB

Published:

2019-08-22

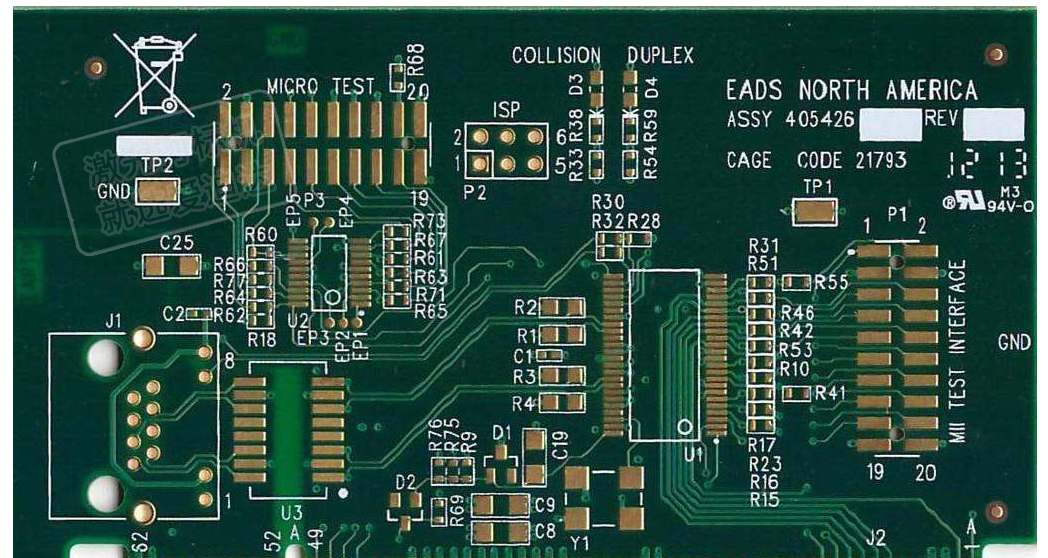

LaserMarkingMachineforPCB PCB(PrintedCircuitBoard),alsoknownasprintedcircuitboard(PCB)inChinese,isanimportantelectroniccomponent,thesupportofelectroniccomponents,andthecarrierofelectricalconnectionofelectroniccomponents.Becauseitismadebyelectronicprinting,itiscalled"printed"circuitboard. Atthesametime,PCBistheupstreamofalmostallelectronicconsumergoods,whethermobilephones,computers,tablets,displayscreens,etc.,willbeusedinPCB,whichhasawiderangeofapplications.DuetothecomplexstructureandnumerouspartsofPCBcircuitboard,markingandmarkingwillbecarriedoutonPCBcircuitboardforconvenienceofapplication,buttraditionalprintingisdifficulttomeettheincreasingtechnologicalrequirementsduetobackwardprocessanddemand,andhigh-efficiencyprintingandmarkingoflasermarkingmachinehasbeenwidelyused. Today,jingweiLaserandtheintroductionofthelasermarkingmachineonthePCBcircuitboardapplicationofmarkingprocessingmainlysilkprintingandlasermarkingtwokinds.Thetraditionalsilkprintingprocessisroughandthelogoiseasytofalloff,whichmakesitinconvenientforuserstouse.Inaddition,thesilkprintingprocessiscumbersomeandrequirestimelyreplacementofoperatorstoensureproductionefficiencyandincreaselaborcosts. Lasermarkingmachine,withitsprecisionandflexibility,canmakeupfortheinadequacyofsilkprinting,andgraduallybecomethebestprocessingtoolforPCBmarking.Itwillplayadecisiveroleinthecircuitboardindustry.Lasermarkertechnologycanhopmark,realizeonething,onecode,marktwo-dimensionalcodeonPCB,canachievequalitytraceability,sothatuserscanknowproductinformationbyonekey. LasermarkingisamarkingmethodthatuseshighenergydensitylasertoirradiatePCBplatelocally,soastovaporizethesurfacematerialorchangethecolorofthechemicalreaction,thusleavingapermanentmarking.Lasermarkingcanproduceallkindsofcharacters,symbolsandpatterns.Thesizeofcharacterscanrangefrommillimetertomicrometer,whichhasspecialsignificanceforanti-counterfeitingofproducts. WhataretheadvantagesoflasermarkingmachineforPCBcircuitboard?HighPrecision:Lasermarkingisfine,preciseandnon-contactprocessing.Itcanprintfinelineslessthan0.1mmonthesurfaceofmaterialsandcharactersandnumberslessthan0.5mm.Itisespeciallysuitableforthemarkingofminimalgraphicsandcharacterssuchasprintedcircuitboards._High-quality:Electronicchiphashigherrequirementsformarkingquality,clarityandpermanence.Lasermarkingcanachievepermanentandclearmarkingofchipwithoutfadingmarkingduetoexternalfactorssuchashighandlowtemperature,acidandalkaline,frictionandsoon._Safetyandenvironmentalprotection:Onlyasmallamountofgasisproducedanddischargedthroughexhaust,withouttheassistanceofchemicalsubstances,toprotectthesafetyofoperatorsandworkingenvironmentasfaraspossible._TheapplicationofPCBspeciallasermarkingmachinecanobviouslyimprovetheproductionefficiencyandproductyield,savealotofcostofconsumables,andtheoperationofautomaticproductionlinealsoreducesthelaborcost,sothatyourfactorycanstandoutinthecompetitionofthesameindustryandtaketheleadbyawidemargin.ThespeciallasermarkerforPCBcircuitboarddevelopedbylongitudeandlatitudelasercanhelpthePCBindustrycompleteperfectmarkingoperationandrelatedmarkingbehavior,andprovideacompletesetofsolutionsforlaserequipmentprocessingforPCBmanufacturers.WelcometoPCBcircuitboardindustry.

for,the,and,of,marking,pcb,laser,to,is

Latest News

CONTACT US

Please Send The Contact Email To

Welcome to inquire

LIAOCHENG JINGWEI LASER EQUIPMENT CO.,LTD

Address:No. 111, Baililai Kechuang Town, Intersection of Hunan Road and Xindonghuan, Liaocheng High-tech Zone, Liaocheng, Shandong, China

Whatsapp:+86-19963537926

Mob:+86-19963537926

MESSAGE